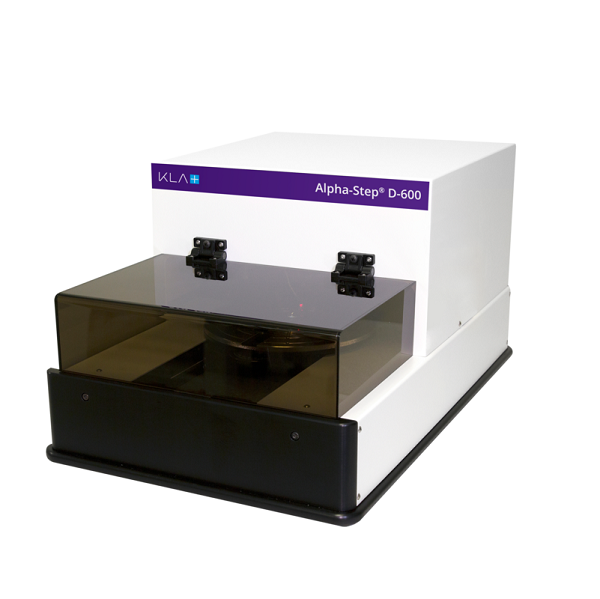

I. Product Description

The Alpha-Step D-600 stylus profiler supports 2D and 3D measurements of step heights and roughness, plus 2D bow and stress. The innovative optical lever sensor technology offers high resolution measurements, large vertical range and low force measurement capability.An advantage of the stylus measurement technique is that it is a direct measurement, independent of material properties. Adjustable force and choice of stylus enable accurate measurements of a wide variety of structures and materials. This enables quantification of your process to determine the amount of material added or removed, plus any changes in structure by measuring roughness and stress.

II.Functions and Features

Features

Step Height: Nanometers to 1200µm

· Low Force: 0.03 to 15mg

· Video: 5MP high-resolution color camera

· Keystone Correction: Removes distortion due to side view optics

· Arc Correction: Removes error due to arc motion of the stylus

· Compact Size: Small system footprint

Software: User friendly software interfac

Applications

· Step Height: 2D and 3D step height

· Texture: 2D and 3D roughness and waviness

· Form: 2D bow and shape

· Stress: 2D thin film stress

Industries

· Universities, research labs and institutes

· Semiconductor and compound semiconductor

· LED: Light emitting diodes

· Solar

· MEMS: Micro-electro-mechanical systems

· Automotive

· Medical devices

· And more: Contact us with your requirements

III.Applications Details

Step Height

The Alpha-Step D-600 stylus profiler is capable of measuring 2D and 3D step heights from nanometers to 1200µm. This enables quantification of material deposited or removed from processes such as etch, sputter, SIMS, deposition, spin coatings, CMP and other processes. The Alpha-Step series has low force capability that enables measurement of soft materials, such as photoresist.

Texture: Roughness and Waviness

The Alpha-Step D-600 measures 2D and 3D texture, quantifying the sample's roughness and waviness. Software filters separate the measurement into the roughness and waviness components and calculate parameters such as root mean square (RMS) roughness.

Form: Bow and Shape

The Alpha-Step D-600 can measure the 2D shape or bow of a surface. This includes measurement of wafer bow that can result from mismatch between layers during the device fabrication, such as the deposition of multiple layers for the production of semiconductor or compound semiconductor devices. The D-600 can also quantify the height and radius of curvature of structures, such as a lens.

Stress: 2D Thin Film Stress

The Alpha-Step D-600 is capable of measuring stress induced during the manufacture of devices with multiple process layers, such as semiconductor or compound semiconductor devices. The bow of the sample is accurately measured using a stress chuck to support the sample in a neutral position. The change in shape from a process such as film deposition is then used to calculate the stress by applying Stoney's equation.